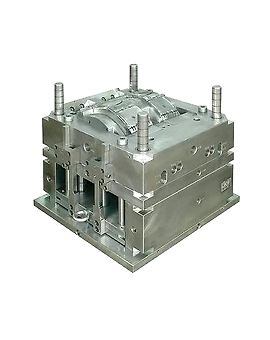

Mold Manufacturing

Mold Manufacturing

This our most important strength.

With a thorough understanding of crucial dimensions and tolerances , product profiles and product function we carry out DFM analysis to confirm feasibility for manufacture else suggest amendments to the extent required to meet the requirements. These amendments are included in product design only post client approval.

Based on this clear understanding our tool designers come up with layout and fiat draft of mould design which is duly cheeked and approved by team leaders for further completion.

Our mould designs address not only product profiles and tolerances , but necessarily type of steel , strength of steel sections ,foolproof working of mechanisms and robustness of structure for strength and function. Wherever scope exists mould flow analysis is utilised to ensure necessary provisions for uniform fill , for minimising effects of shrinkage and warpage , for as desired finish and strength and for optimum processing parameters.

Mould design completion entails detailed process plan with an aim to run possible processes parallel to each other and save time. Day to day monitoring and QA ensures the process continues and completed in time as planned. Tools like Gantt chart are used to keep track of progress and to update client periodically.

A final QA with measurement of crucial dimensions , dry run of mechanisms is conducted to ensure mould is ready for trial T0.